New rock breakers: year of the 7

5 new models of hydraulic breakers are enriching Montabert‘s range of heavy hammers. These are upgrades of 5 existing models, with the old versions being replaced:

- The XL 2700 replaces the XL 2600

- The V 4700 replaces the V4 500

- The V 47 replaces the V45 and V46

- The V 57 replaces the V55 and V56

- The V 67 replaces the V65

These new models have benefited from all the technical advancements developed by Montabert over the past years, allowing these hammers to offer even higher performance than their predecessors. They have also been designed to be maintained at a lower cost, notably through the use of repairable components. Still manufactured in France, at the Saint-Priest factory near Lyon, these new breakers have already begun operating. The XL2700 and V4700 are already available (several XL2700 units are in operation at TELT, the tunnel between Lyon and Torino). The V47, V57, and V67 will be available in spring.

CPA next generation

Montabert is introducing a new series of drilling masts, hydraulic attachments that transform an excavator into a surface drilling machine.

With extensive experience in this type of attachments, Montabert has taken these products to a new level by incorporating new technologies and enhancing existing products.

The three largest models are already available. The CPA 28-050 will be available later in 2024.

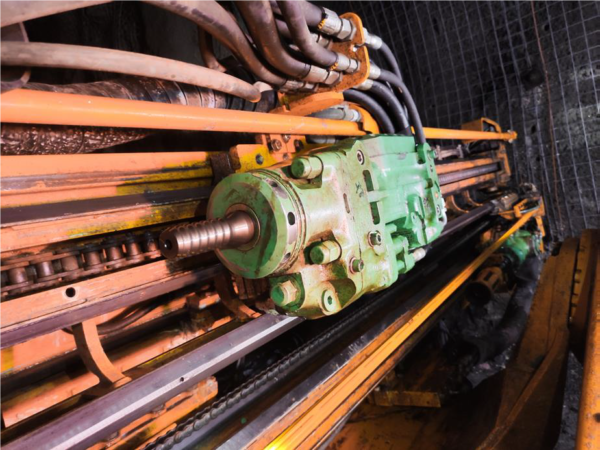

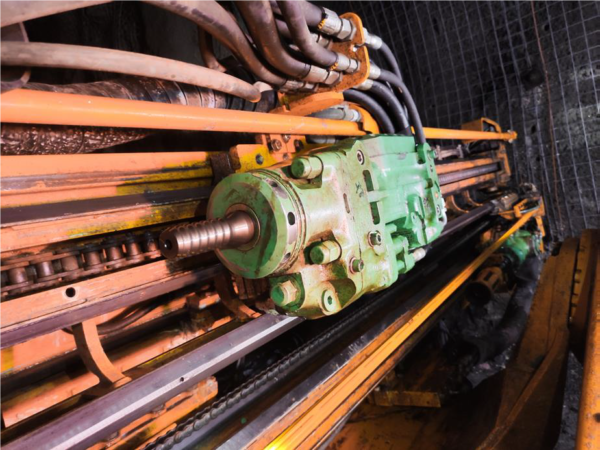

HC 55: the most compact of Montabert drifters

Montabert launches the most compact and fastest drill in its range: the HC 55. This new drill is a true quintessence of innovative technologies: no less than 4 patents have been filed for this model! One of the major and impactful developments on productivity is the new hydraulic dampener, capable of great rock condition responsiveness and automatically adapting the drill’s operation based on the rock.

Primarily dedicated to bolting applications, this 15 kW drill is very easy to install on drillrigs, with its minimal footprint, reversibility, and symmetrical connections. Designed to withstand the toughest applications and the most extreme working environments, the nose of the HC 55 has been reinforced to resist corrosion and equipped with enhanced sealing through 5 seals and an additional protection system, further extending the lifespan of wear parts.

The HC 55 is compatible with R 28 and R 32 female couplings, as well as R 32 ,R 38, and T 38 male couplings. It is available now for purchase.

Silent demolition tools

Montabert now offers a complete range of silent demolition tools:

- Sorting and demolition grabs (HCG range)

- Universal grabs (HCG-U range)

- Multi-processors with concrete combi jaw (HCM-C range)

- Multi-processors with multi-function jaw (HCM-M range)

- Multi-processors with scrap jaw (HCM-S range)

- Fixed and rotating pulverizers (HCP and HCP-R ranges)

- Scrap shears (HCS range)

These products are manufactured in Germany, following the same quality standards and professionalism as the rock breakers and drills produced at the Saint-Priest factory. The entire range is already available.

OMNI-M monitoring system

Today, there is often talk in our industry about themes like Industry 4.0 or the IoT (Internet of Things), which essentially represent the concept of being able to track data related to a device, wherever it is and however it operates.

This need is also valid for hydraulic breakers. That’s why Montabert has decided to work on a device that is as ergonomic as it is reliable, allowing Montabert hammer users to remotely monitor their equipment. After several years of trials and research, Montabert is now able to offer a solution to its customers: the OMNI-M device.

If we were to summarize the main functionalities of this new accessory in two ideas, they would be the following: tracking working hours and location.

Road to decarbonation

Montabert is working on its decarbonization goal on multiple fronts simultaneously:

- Complete carbon footprint calculation: Montabert has begun this year, with the help of a partner, a comprehensive calculation of its carbon footprint, encompassing all cycles related to the finished product. From production to end-of life, all stages will be accounted for to obtain the most precise and realistic analysis possible.

- Reshoring strategy: ‘Made in France’ is not just a slogan at Montabert. For over 100 years, products have been designed and manufactured from a single site in the Lyon region (there have been three relocations, but the company has always remained within Lyon or its outskirts). The industrial policy continues to favor employment and investment at this same site to uphold this local vision. Moreover, by making 72% of its purchases in France (71% within 200 km of the factory and 88% within 400 km), Montabert bolsters local job markets.

- Circulareconomy: Why extract raw materials when they’re already present in products?Montabert is currently working on sharing, reusing, repairing, renovating, and recycling existing products and materials for as long as possible to maintain their value and performance. This extends the products’ life cycle and minimizes waste.

- Commitment for the future: Montabert aims to share its approach with other industries to continue its self-reflection and exchange practices. This is why the company has joined the CEC (Convention of Companies for the Climate) with the ambition to co-create new environmentally friendly economic models and implement them through operational road maps and concrete collaborative projects. The goal is to transform the industrial landscape sustainably by reconciling ecology, economy, and social aspects while respecting planetary boundaries.