For the first time at Ecomondo, Pavilion A3, stand 205-104, the new mobile screener NHEXА makes its debut.

Compact, flexible, and designed for maximum operational efficiency, NHEXА is a high-performance mobile screener capable of operating effectively even in the tightest spaces and under the most demanding working conditions. Thanks to its intelligent design and cutting-edge technology, NHEXА ensures excellent separation quality while offering easy transport, quick setup, and simple maintenance.

Ecostar expands its product range with NHEXА, a new mobile screening solution designed to deliver maximum performance in limited spaces. NHEXА is the ideal answer for low to medium throughput applications and for plants requiring precise and efficient separation of heterogeneous materials, even under challenging operating conditions

Compact, flexible, and efficient

NHEXА is designed to achieve throughput rates of up to 50 T/H across a range of applications. Featuring a 5-meter screening surface, NHEXА can be configured for 2 or 3 fractions with section sizes from 15 to 150 mm, ensuring excellent operational versatility. Its compact design and tracked configuration allow easy positioning in tight areas, on rough terrain, or directly at landfill sites.

Suitable for all material types

NHEXА is built to handle a wide variety of materials, including: municipal solid waste (MSW), refuse-derived fuel (RDF), organic waste, industrial waste, construction and demolition debris, compost, recycled wood, biomass, car fluff, and incinerator bottom ash.

The machine ensures high-quality separation even with wet, sticky, or otherwise difficult materials.

Maximum efficiency, simplified maintenance

Thanks to its modular screening surface and hydraulically operated side covers, NHEXА allows fast and safe maintenance operations. Shaft and section replacement is quick and easy, minimizing downtime and maximizing daily productivity.

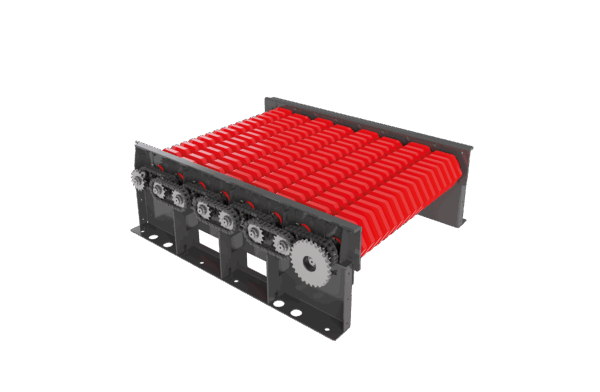

Patented Dynamic Disc Screening technology

At the heart of NHEXА lies the patented Dynamic Disc Screening (DDS) technology, which ensures accurate and efficient separation, even with challenging materials. Thanks to the flat-profile hexagonal or octagonal disc design, the material flows on the screen’s discs and is subjected to a jolting movement that separates the waste. The undersized material drops below the screening surface, passing through the gaps between the discs while the oversized material advances to the end of the screening plane. The result is a clean fraction, ready for recycling processing.

Another advantage of DDS technology is the ability to fine-tune the screening section (±30%) in real time by simply adjusting shaft speed.

For even more challenging materials, Ecostar has developed and patented the Hyper Dynamic Disc Screening (HDDS) technology, which further enhances separation quality and is also available on the NHEXА platform.

Anti-wrapping system: less downtime, more efficiency

NHEXА is equipped with a patented anti-wrapping system. The drive shaft is protected by highly resistant loose manifolds which are independent of the rotation of the shaft itself. This prevents long and stringy parts of the material being screened from getting wrapped around the shaft, optimizing the separation and significantly reducing downtime.

Adaptable and ready for any worksite

With its flexible side discharge belt configuration, NHEXА can be easily adapted to any operational layout, optimizing material flow and site space.

An all-Italian collaboration

NHEXА is the result of a partnership between Ecostar and Komplet, a well-known Italian company specializing in modular and compact solutions for waste treatment and recycling. This collaboration combines expertise, vision, and engineering capability to deliver a high-performance, user-friendly, and easy-to-transport screening machine – designed for today’s and tomorrow’s environmental challenges.

About Ecostar

Ecostar is synonymous with the most advanced and refined technology in the mechanical separation of waste and recyclable materials since 1997. The research and development made by Ecostar have created personalized solutions for every type of material to be screened. Thanks to the patented Dynamic Disc Screening technology, today many types of waste can be efficiently used to supply clean fuels and energy sources, such as biomass and RDF, or substances useful for agriculture and forestry, such as compost.

Headquartered in Sandrigo – Italy, Ecostar is present in 49 countries around the world.

For more information, you can visit: www.ecostar.eu.com