According to the Federal Environment Agency, around 3.33 million tonnes of plastic waste were recycled or reused as raw materials in Germany in 2019. More than 38 per cent of this was polypropylene (PP), which has many uses, such as for food packaging, various containers, but also for interior fittings in vehicles, technical and electronic components. However, most polypropylene recyclates often have a melt flow index that is only suitable for further processing to a limited extent. The addition of peroxide masterbatches, however, enables further processing in injection moulding: the MFI increases, the PP becomes significantly more flowable, and this already with a peroxide masterbatch starting at 0.1%.

Especially in view of the EU recycling quotas, which are to be further increased by 2030, peroxide masterbatches are becoming increasingly important in the recycling of plastics. This is because the polypropylene obtained from the mechanical pre-sorting of various material streams often has a lower melt flow index, which precludes further processing of the thermoplastic in the injection moulding process. The MFI is usually in a range that is neither suitable for further processing in extrusion nor for injection moulding. Especially in applications where a short cycle time is absolutely necessary, recycled polypropylene to which no peroxide masterbatch has been added cannot be used. Due to the sometimes very long polymer chains, the melt flow index is too low.

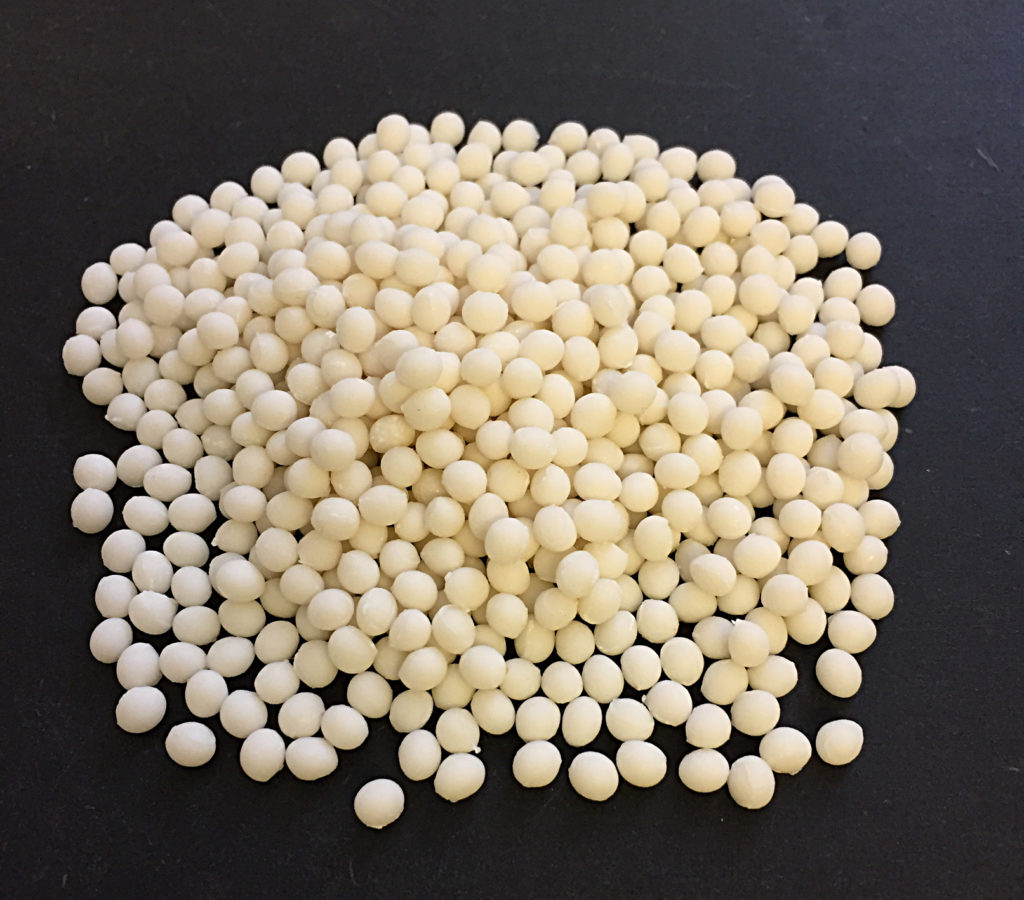

For this reason, peroxide is used to shorten the long polymer chains of the polypropylene and thus increase the melt flow index. However, both in liquid and powder form, the transport and especially the handling of the flammable, highly reactive and sometimes explosive chemical are subject to very strict safety regulations. The necessary protective equipment and special dosing technology further complicate the entire handling process. In addition, the peroxides are volatile and thus have a limited shelf life even when stored correctly. With its P-series masterbatches, however, Polyvel Europe GmbH has developed an alternative that is safe to handle and easy to dose. Thanks to the available additive concentrations of 5, 10 and 20 per cent peroxide, the flow behaviour of polypropylene can be specifically optimised in this way.

Safe and easy improvement of the melt flow index

Polyvel’s peroxide masterbatches can be used to precisely modify the processing properties of polypropylene. “The chemical is incorporated into a polymeric carrier material and then converted into granule form,” says Sebbel. “In this way, the peroxide is encapsulated from environmental influences until the time of processing.” In granulate form, the peroxide can be stored for over five years because it cannot volatilise. Transport and storage are uncomplicated and possible without special conditions or requirements. Accordingly, no special requirements have to be met during handling, the application is particularly safe and, moreover, in contrast to liquid or powdered peroxide, very simple. No special devices are needed for dosing either.

Peroxide masterbatches can be used to modify the viscosity in a targeted manner, which leads to an increase in the melt flow index of the polypropylene. On the one hand, this makes it possible to process recycled polypropylene in injection moulding in the first place, and on the other hand, the peroxide masterbatch can also be dosed directly in the injection moulding process to further increase the flowability. In many cases, thin-walled components with long flow paths can be produced more reliably and with greater process reliability.

Furthermore, the higher flowability allows for a lower processing temperature, which means that the cooling time can be reduced, thus decreasing the overall cycle time and increasing productivity, which ultimately means lower production costs.

The results can be reliably reproduced due to the predictable dosing of the masterbatches. By being able to adjust the melt flow of polypropylene so precisely and cost-effectively, recyclates can also be processed as a higher-quality starting material. In this way, expensive primary raw materials can ultimately be saved in the production of plastic components and products.

Easier handling and finer dosage options

Usual dosing quantities for the peroxide masterbatch are between 0.1 and 1 per cent. “With such small addition quantities, it is a particular challenge to introduce them evenly into the continuous compounding process over a long period of time,” explains Sebbel. “The granular form of the masterbatches makes this much easier, because it allows you to achieve a very homogeneous distribution in the polypropylene. Due to the different peroxide contents, both small and large MFI jumps can be precisely adjusted.”

While the melt flow index of polypropylene increases due to the peroxide, polyethylene, on the other hand, becomes more viscous, which is advantageous for the respective processing methods such as film extrusion and blow moulding. In this way, the P-Series masterbatches ultimately simplify the recycling processes of different thermoplastics.

More information on the internet at www.polyvel-europe.com